Revolve™ - First Sustainable Wipes Made for the Cleanroom Industry

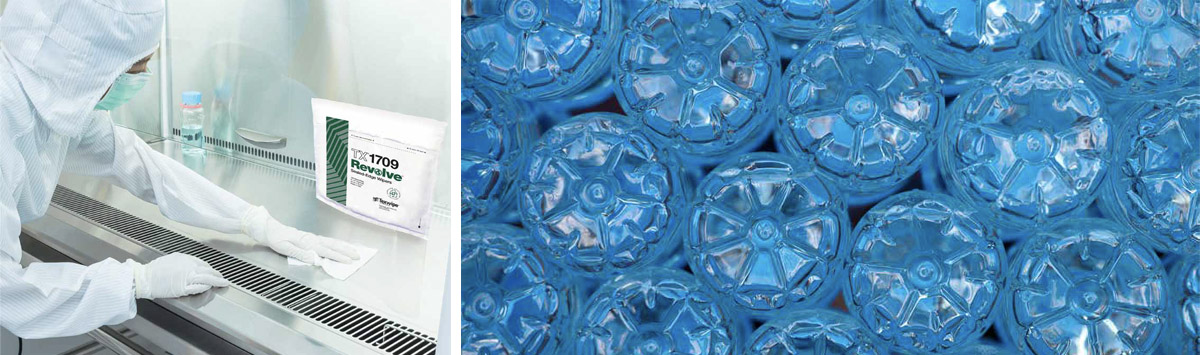

Revolve™ wipers, the first sustainable wipers made for the cleanroom industry, are made from 100% upcycled polyester material with a sealed edge, processed on Texwipe’s fully automated manufacturing system. Revolve™ wipers contribute to the sustainability goals, reducing the amount of post-consumer water bottles going into landfill and reducing the level of carbon emissions. By using Revolve™ products, companies participate in the reuse of polyester polymers, saving the number of bottles indicated on each product bag.

Our sustainable wipers can be used in wide range of applications in cleanroom:

- Wiping and cleaning surfaces, equipment and parts.

- Applying and removing lubricants, adhesives, residues and other solutions including disinfectants.

- Cleaning with solvents such as isopropyl alcohol (IPA), ethanol, acetone, and degreasers.

- Lining trays for holding, protecting, drying and storing of parts, equipment and devices.

- Dry Wipers: Appropriate for use with temperatures less than 400°F (205°C).

Unleashing the Power of Upcycled Polyester:

Traditionally, the manufacturing of polyester wipers relied on virgin polyester. However, Texwipe's Revolve™ line is breaking new ground by utilizing upcycled post-consumer water bottles. High-quality polyester yarn is created through an intricate process of cleaning, grinding, and melting the bottles. This yarn is used in the regular knitting process to form the fabric used for Revolve™ wipers and mop covers.

Revolve™: Cleanliness and Performance at Par:

Texwipe has not compromised on performance regarding the Revolve™ line of products. Extensive research and development efforts have ensured that Revolve™ wipers offer the same cleanliness, sorption rate, capacity, particle and fiber control, and the absence of ions and nonvolatile residues compared to wipers made from virgin polyester. Texwipe's commitment to maintaining the highest industry standards has made Revolve™ a reliable choice for cleanroom applications.

Ensuring Microbial Cleanliness:

One might wonder if Revolve™, made from upcycled bottles, can guarantee microbial cleanliness for sensitive environments. Texwipe leaves no stone unturned in the manufacturing process to ensure the highest level of cleanliness. The collected bottles undergo sorting, washing at high temperatures, repolymerization, and extruding, eliminating all possible microbes. Furthermore, Texwipe's meticulous fabric processing further eliminates any remaining contaminants. For the most critical sterile applications, Revolve™ offers a range of sterile products that are gamma-irradiated and validated to a sterility assurance level of 10-6 as per AAMI guidelines.

Performance on Par with Virgin Polyester:

Revolve™ has undergone rigorous testing to assess its performance characteristics, such as absorbency (sorption rate and sorption capacity), particle and fiber control, and ions and nonvolatile residue levels. The results have shown that Revolve™ wipers perform comparably to wipers made from virgin polyester, adhering to industry standards for cleanliness and performance. This ensures that Revolve™ can be trusted for even the most critical and demanding cleanroom applications.

A Sustainable Solution for the Future:

One of the most significant advantages of Revolve™ is its sustainability. By using upcycled post-consumer water bottles, the Revolve™ line contributes to the reuse of polyester polymers, thus reducing the number of bottles destined for landfills. Each Revolve™ product bag proudly displays the number of bottles required to manufacture it, serving as a testament to the positive environmental impact.

Texwipe innovates to create products that fit the necessity of the market and provide a high-quality performance for the industries. Revolve is an innovation that will help the customers and the environment. They have been created to be used in all different industries:

- Aerospace

- Cleannroom Building/Design

- Animal Laboratory

- Biologics

- Industrial

- Data Storage

- Medical device

- Microelectonics

- Pharmaceutical

- Semiconductor

Every bag of Revolve™ product indicates the number of post-consumer water bottles used to make it. For example, 47 water bottles are required to make one bag of TX1709 wipers. By using the Revolve™ products, your company will participate in the reuse of the polyester polymer, saving the number of bottles indicated on each Revolve™ product bag from going into landfill. Texwipe does not add any other types of yarn to the wiper in the process.

You can see more information in the Revolve Brochure or contacting our experts. Click here to see our Revolve products.