Cleanroom Wipers and sustainability, a contradiction?

More and more sustainability becomes a topic for all aspects of life – therefore also for our work environments.

How can we do it – or is it even possible – to use cleanroom wipers in a more sustainable way, without increasing the risk of contamination?

A question we can hear very often is: “Most of the cleanroom wipers are made of 100% polyester – wouldn’t it be possible to collect and recycle them? “The answer is in principle yes, but the problem is that the wipers are used to pick up all kinds of residues, including toxic, infectious, hazardous and many other critical substances. No recycling company can assess the possible risk. So, we must look for different, more appropriate ways.

One path Texwipe walked in 2020, was the introduction of Revolve™, the first complete cleanroom product line made of “up”cycled polyester-yarn.

Texwipe did extensive research on the performance characteristics of rPET-made polyester compared to virgin polyester material. The rPET materials were processed through Texwipe's manufacturing lines and demonstrated equivalent properties as virgin material.

With these results, a new line of products was born, culminating in the launch of Revolve™ products.

All products are made from 100% upcycled polyester material.

Upcycle→ to recycle something in such a way that the resulting product is of a higher value than the original item

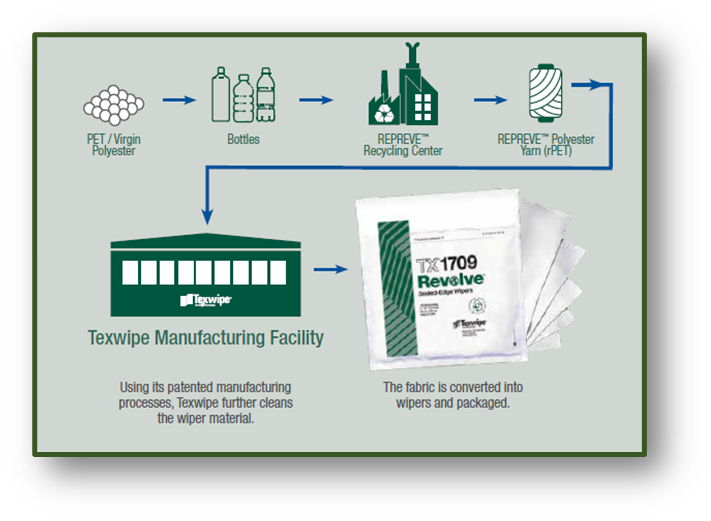

How is Revolve™ made?

The polyester yarn used to make Revolve™ products is derived from post-consumer bottles. The bottles are collected and sent to the recycling center where they are sorted, cleaned, ground, repolymerized into chip, and extruded to make the REPREVE™ yarn. Texwipe uses the REPREVE™ yarn to make the wiper fabric and then further cleans it to meet Texwipe’s standards for the cleanroom industry. Using the upcycled yarn substantially reduces the consumption of natural resources and thus lessen the carbon footprint.

But another step into more sustainability is certainly alsothe optimization of processes. This includes the suitable wiper selection for the individual cleaning procedure, but also the adjusted quantity in an optimal packaging. This requires a careful analysis of processes and a risk assessment to find the most appropriate one from a wide range of cleanroom wipers.

However, it can also make perfect sense to deviate from standard products available on the market and develop a special customized cleanroom wiper which is directly designed for individual manufacturing processes. This can be a special material, like we use it for Revolve™ , as well as a special wiper or packaging size. In addition to that it might be a good idea to think about special designs (folding) or different saturations. All this can help to save material and to reduce waste.

With its manufacturing operations in the Netherlands Texwipe has the capability to be responsive and very flexible on individual requirements coming from the customer or coming from the local market and offer a constantly growing product portfolio on customized cleanroom wipers.

This growing number of Texwipe cleanroom wipers made in EU brings us another benefit for our request on sustainability shorter transport routes and with that a more stable supply chain in the long term.

In a summary it can be said that, despite all the difficulties in using disposables, it is already possible to clean a cleanroom in a more sustainable way. Texwipe will continue to work on offering more products helping to reduce the consumption of natural resources.

Important to note:

- There’s not one wiper for all applications

- Optimization of contamination control with cleanroom wipers and their consumption requires close cooperation between manufacturer and end user

- An optimization results in a reduction of risks and costs - and in the best case it is also sustainable.